Membranes are divided into two major groups:

- Filtration Membranes – carrying out physical filtration to very high quality up to 0.002 microns. This is done by the technology of Microfiltration (MF) and Ultrafiltration (UF).

- Desalination Membranes – this technology treats the water to an ion level separation.

Microfiltration and Ultrafiltration

This technology is used to treat surface water, ground water, sea water and waste water as either primary treatment or as pretreatment to reverse osmosis and nanofiltration. MF and UF is a pressure-driven membrane separation process that helps removes particulate matter from aqueous solutions such as water. The relative small pore sizes efficiently remove bacteria and most viruses, colloids and silt. The smaller the nominal pore size, the higher the removal efficiency.

Typically the MF & UF is operated at a constant permeate flow. The transmembrane pressure (TMP) will naturally increase over time, and the module can be cleaned by back-washing and air-scouring to remove the fouling layer for longer service life.

The MF and UF membranes are built from hollow fibers. The hollow fibers are molded together to create membranes. The differences between manufacturers are:

- Fiber construction materials

- Filtration direction in the hollow fiber: Outside-In or Inside-Out

- Backwash will be the opposite of the filtration mode

- Operating MF & UF can be either dead-end or cross-flow (concentrate bleed)

Desalination

Membrane technology enables the treatment of water to a very high quality which means the elimination of most of the ions in the water. OKiana designs, builds, installs and maintains reverse osmosis for different capacities from a few cubic meters up to two thousand cubic meters.

Membrane technology is used in the following applications:

- Tap water

- Brackish water

- Sea water

- Waste water

We utilize leading membrane manufacturers, such as Hydranautics, Dow etc.

For our reverse osmosis solutions for sea water desalination, we utilize top quality equipment for energy recovery to achieve energy savings.

Reverse Osmosis and Membranes Technology

Reverse osmosis is a fundamental component of treatment systems for the water used in many industrial, municipal and agricultural applications as well.

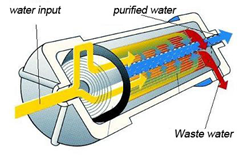

Reverse osmosis is the process of ion separation from water. The feed water stream is separated into a stream of purified water and a stream of concentrated solutes and particulates.

The mechanism of reverse osmosis is different from filtration in that physical holes may not exist in an RO membrane (its pores are believed to be less than 0.001 micron). It is more likely that water and smaller molecular weight organics are able to diffuse through the membranes polymer by bonding between segments of the polymer’s chemical structure.

The process of separation occurs by applying pressure on the membranes. Dissolved salts and larger molecular weight organics will not permeate the membrane as readily, however, because of their size and charge characteristics. The clean water with very small amounts of impurities passes the membranes and is collected as permeate water, while the solution with the molecules that cannot pass through the membranes is collected as concentrate.

A cross section of membrane in operation:

Illustration of media filters and reverse osmosis: